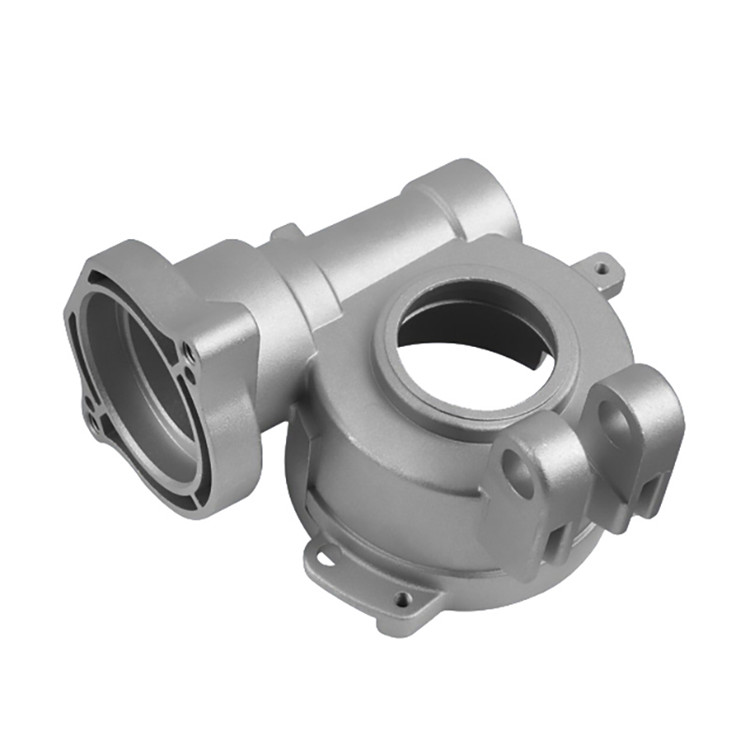

Zinc Alloy Die-Casting Parts |Professional OEM Die Casting

✧ Product Sumo

Zinc die castings inoshandiswa kugadzira zvikamu zvakasiyana uye zvikamu mumhando dzakawanda dzemaindasitiri ekushandisa.Iyo mechanic zvimiro zvezinc alloy die castings pakupisa kwekamuri zviri nani pane izvo zvegrey iron, ndarira uye aluminium jecha castings, kunyanya maererano nekuoma uye simba rekuita.Iwo akasimba, akasimba uye akanyanya kugadzikana pane majekiseni akaumbwa mapurasitiki.Kuderedzwa kwemutengo uye kuita kwakagadziridzwa kunoita kuti ive yakanakira kutsiva simbi, mhangura, aluminium alloy kana zvikamu zvepurasitiki.

Zvakanakira zinc alloy die casting

1. Kuvandudzwa kwekukanda zvinhu - nekuda kwekuyerera kwayo, zinc die castings inogona kuitwa yakaonda, yakaoma uye yakaoma, nokudaro kubvisa kudiwa kwechipiri kugadzirisa iyo inowanzofanira kuitwa nealuminium uye magnesium alloys.

2. Kupfupisa nguva yekutenderera - nekuda kwekupisa-chamber casting process ye zinc, iyo yakabuda inenge 4 kusvika 5 zvidimbu paminiti.Kuenzaniswa nealuminium inotonhora kamuri yekukanda nzira yekukanda (inoburitsa 2 kusvika ku3 mashiti paminiti), zvinogona kutariswa kuti zinc inogona kuwedzera iyo yese yekuchengetedza nekuda kwekupfupika kutenderera nguva.

3. Wedzera hupenyu hwehutu - nekuda kwekuderera kwekushisa kwe zinc, hupenyu hwehuputi hwezvikamu zvezinc hunogona kuva 10 nguva yakareba kupfuura iyo yealuminium alloy castings, uye inenge 5 nguva yakareba kupfuura iyo ye magnesium molds.

4. Ideal mechanical quality - zinc alloy yakasimba kudarika mamwe masimbi akafanana uye haifaniri kushandiswa kwechipiri.Hunhu uhu hunochengetedza mari yese yechikamu chimwe nechimwe.

✧ Zvigadzirwa Tsananguro

| Mold Material | SKD61, H13 |

| Cavity | Imwe kana yakawanda |

| Mold Hupenyu Nguva | 50K nguva |

| Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

| Surface Treatment | 1) Polish, poda coating, lacquer coating, e-coating, jecha blast, kupfura kuputika, anodine 2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/mhangura plating |

| Size | 1) Zvinoenderana nemifananidzo yevatengi 2) Maererano nemasampuli evatengi |

| Drawing Format | nhanho, dwg, igs, pdf |

| Zvitupa | ISO 9001:2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |